Great Slide cleaning polish and slickcoat sealant developed by and exclusively used and sold by the Slide Doctor

Lightning Fast Slides

Great Slide is a new polymer product used & provided exclusively by the Slide Doctor.

Great Slide Cleaning Polish removes oxidation and contaminants from the inside of outer trombone tubes, as well as from the external surfaces of all brass instruments.

Great Slide Slickcoat Sealant provides maximum polymer protection against oxidation and contaminants to the inside of outer trombone tubes, and it delivers an ultra slick sealant that minimizes friction between inner and outer trombone tubes, resulting in ultra smooth slide action.

Great Slide Slickcoat Sealant also delivers deep shine and long-lasting protection to the external surfaces of all brass instruments.

Great Slide is a combination of natural and synthetic polymers which can greatly enhance slide action.

Used exclusively by the Slide Doctor & now available directly to players!

The new polymer products we use are called

GREAT SLIDE CLEANING POLISH & GREAT SLIDE SLICKCOAT SEALANT.

It is a blend of synthetic and natural polymers that contains no Teflon!

Environmentally friendly!

History

The Slide Doctor started using polymers about 20 years ago to improve slide function. The process was just an epiphany that resulted from having an elderly bell with scratches through the lacquer. He decided to “wax” the bell with some auto polish (which included both Teflon and polymer components.) To his surprise, the areas that were scratched became shiny and much smoother and the polymers kept the brass shining for months afterward. Well, if the results were this good on the brass outside surfaces, how would it work on the inside of the outer tubes?

After a period of time, the auto wax that was used was removed from the market. A variety of other polymer-based products were tried and one was located that worked better than the original. What do we mean by “worked?”

Polymers

You encounter polymers all the time. Natural polymers come from trees! For example, rubber is a polymer that is soft, but can be made harder by altering the molecular structure. Synthetic polymers have been chemically altered to make them either harder or softer as well as to have other useful properties.

These little balls of polymer are about a micron in diameter. Alter their properties so that they will attach themselves to a metal surface. Use enough little balls and fill the valleys in the brass so that they no longer constitute a drag on the slide action.

Brass

Brass is not as smooth as it appears. It looks smooth to the naked eye, but in fact, under a microscope brass (and nickel silver) looks something like your skin. It is a porous metal. Herein lies the big problem with all types of lubrication.

To make the tube slick, lubrication fills the valley and provides a more uniformly flat, or smooth, surface. However, over time, the lubrication degrades, becomes sticky and can build up, actually making the slide function slower rather than faster.

Rather than to allow lubrication to fill the valleys, we have discovered that polymers do the job better and they do not degrade as lubricants do, which will gum up over time. A blend of natural and synthetic polymers, held in suspension in a medium that will evaporate fairly easily, allows us to transfer the polymers to the inside of the outer tubes. Assuming that the tubes are uniformly round and straight, the result is that the outside tube will move amazingly fast on the inside tube with no additional lubrication.

Function

For polymers to function properly, the inside of the outer tubes should be as clean as possible. This is where the “clean” comes in. The cleaner the inside of the outer tube, the better the polymer adheres to the brass and the longer it will function without an additional application. This is why we use multiple applications of Goddard’s Brass and Copper Polish™ to remove old lubrication and to remove the real enemy of slide function, “OXIDATION!”

Brass and nickel silver both contain large portions of copper. Have you ever seen an old penny that turned green? Have you ever removed green residue from the inside of your outer slide? That’s copper oxide! Nasty stuff to say the least.

Process

So, first we remove the old slide lube, the oxidation and any other contaminants from the inside of the outer tubes using Goddard’s Brass and Copper Polish™. Then we apply the GREAT SLIDE CLEANING POLISH. This is a petroleum-based cleaner/polish, designed to further clean the valleys in the metal. If you look down the inside of the outer tube after removing the contaminants with the GREAT SLIDE CLEANING POLISH, you’ll see nice shiny metal. Then we apply the GREAT SLIDE SLICKCOAT SEALANT polymers to fill the valleys and make the surface as uniformly smooth as possible.

In speaking with chemists, we are told that there are no negatives in using these products as long as they are not ingested. Great Slide products are for the external components and should not be applied to the mouthpiece.

Benefits

1) A much faster and smoother slide action

2) The oxidation process is slowed as a result of the sealant application

3) The need for lubrication is much less. It requires a smaller amount of lubrication to be applied to the tubes, while allowing the player to use the slide for longer periods of time between cleaning and re-lubrication.

Instructional Videos are available on the resources page and will show you the step-by-step process to apply GREAT SLIDE yourself. Slides that are admitted to the Slide Doctor’s shop are treated with GREAT SLIDE as part of the routine care and rehab of the slide.

Directions

Preparation

It is recommended that you wear rubber gloves and protective eye wear. Use in a well ventilated area.

To get the best results from Great Slide Cleaning Polish and Great Slide Slickcoat Sealant, the inside of the outer tubes must be as clean as possible.

Although it is possible to begin the cleaning process with the Great Slide Cleaning Polish, it is recommended to remove as much oxidation and contaminates as possible prior to using Great Slide products. To do this, we suggest that you clean the inside of the outer tubes with Goddard’s Brass and Copper Polish.

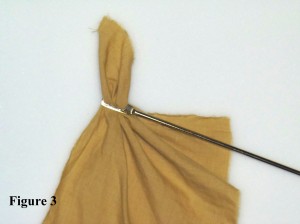

Tear the lint free cloth, such as a bed sheet, 8″ – 14″ wide depending on the bore size of the outer tubes, and 4 feet or longer in length (Fig. 1). Lay the cloth on the cleaning rod so it looks like a flag on a flag pole (Fig. 2). Pull the top corner of the cloth through the eye of the rod (Fig. 3) and wrap it around the top 4 or 5 times, being sure to cover the end of the rod. Then spiral it down covering the rod all the way to the end (Fig. 4). You may need to try it several times to get it “snug” inside the outer tubes.

Cleaning the Slide

IMPORTANT – Be sure to hold the tube you are making the application to or buffing (Fig. 5). Be careful not to hit the crook with the end of the rod.

1) Rinse the inside of the outer tubes and the wrapped cleaning rod with clear warm water.

2) Shake bottle before using. Pour approximately a tablespoon of Goddard’s Brass and Copper Polish to the inside of each outer tube, rotating the tube as you pour.

3) Holding the tube you will be cleaning (Fig. 5), work the wrapped cleaning rod back and forth with short strokes the length of the tube. Be careful not to hit the crook with the end of the rod.

4) Repeat step 3 to the inside of the other outer tube.

5) Rinse the outer tubes with warm water.

6) Repeat Steps 2, 3, 4 and 5 until the rinse water comes out a milky white color.

7) Once the rinse water is colored a milky white, drain, and dry the inside of the outer tubes.

Great Slide Cleaning Polish

1) Shake bottle before using. Apply a tablespoon of Great Slide Cleaning Polish to the end of the wrapped cleaning rod.

2) Holding the tube you will be cleaning and polishing (Fig. 5), work the wrapped cleaning rod back and forth with short strokes the length of the tube. Be careful not to hit the crook with the end of the rod.

3) Repeat steps 1 and 2 to the inside of the other outer tube.

4) Change to a clean, dry, lint free cloth. Holding the tube you will be buffing (Fig. 5), use short strokes throughout the length of each tube, wipe and buff, thoroughly. Be careful not to hit the crook with the end of the rod.

Great Slide Slickcoat Sealant

1) Shake bottle before using. Apply a tablespoon of Great Slide Slickcoat Sealant to the end of the newly wrapped cleaning rod.

2) Holding the tube you will be making the application (Fig. 5), work the wrapped cleaning rod back and forth with short strokes the length of the tube. Be careful not to hit the crook with the end of the rod.

3) Repeat steps 1 and 2 to the inside of the other outer tube.

5) Change to a clean, dry, lint free cloth. Holding the tube you will be buffing (Fig. 5), use short strokes throughout the length of each tube, wipe and buff, thoroughly. Be careful not to hit the crook with the end of the rod.

6) Your slide is ready to use. Apply lubrication and enjoy.

Have a question?

Let's talk slides!